Contents

-

Coffee Processing Methods And How They Affect Flavour

-

When Does Processing Happen?

-

The Natural Process/The Dry Process

-

The Washed Process/The Wet Process

-

The Honey Process/The Pulped Natural Process

-

The Semi-Washed Process/Giling Basah

-

Experimental Coffee Processing Methods

-

What Happens Next?

-

Final Thoughts

There’s more than one way to process coffee. Producers around the world choose from a number of different methods, ranging from the traditional to the more experimental, to increase the yield of their batches and consciously influence quality and flavour.

While you don’t need to know the difference between natural, washed or honey processed coffees to enjoy them, cafes, roasters and specialty coffee retailers are increasingly using these terms as selling points for their beans.

We explore the most common methods used to process coffee, how these methods can change the flavour in your cup, and how farmers make a decision about which approach to use.

Coffee Processing Methods And How they Affect Flavour

|

The Natural Process

|

Fuller body

Less acidity

Potential to highlight earthy notes (chocolate, nuts etc.)

Potential to unleash unique flavour notes

|

|

The Washed Process

|

Higher acidity (bright, lively, fresh)

A cleaner presentation of flavours

Potential to highlight fruity notes (berries, apples)

|

|

The Honey Process

|

Sweeter

Full body

Less acidity

Potential to highlight earthy notes (chocolate, nuts)

|

|

The Semi-Washed Process

*A method typically only used in Indonesia

|

Heavier body

Lower acidity

Potentially highlights earthy notes (tobacco, spice, leather)

|

Tip: Take the above with a pinch of salt. They are generalisations of the kind of profiles that are associated with each method but you can easily find coffees that present very differently, due to several other factors such as location, species, variety, and altitude.

When Does Processing Happen?

Coffee processing happens after coffee cherries have been picked from trees (harvested), which might happen by hand, as is the case on most Colombian coffee farms, or by machine, which may only be done in countries with more even and accessible terrain.

Once collected, these coffee cherries must be processed in a way that separates the outer flesh from the beans inside, before they are dried. This reduces the chance of them rotting while they are stored and gets them ready for the next stages of the coffee’s journey, such as roasting and brewing.

Although the goal of each process is similar (turning raw beans into ‘green beans’), the equipment, time and skill needed for each method is different and producers and coffee cooperatives may be forced to choose an approach due to the resources available to them.

The equipment, time and skill needed for each coffee processing method is different and producers may be forced to choose a certain approach due to the resources that are available to them.

The Coffee Life Cycle

-

Growing

-

Picking (Harvesting)

-

Processing

-

Transport and consolidation

-

Packing

-

Shipping

-

Roasting

-

Sale to consumer

Learn More About the Coffee Supply Chain

The Natural Process / The Dry Process

The natural process is the world’s oldest method of treating coffee. It doesn't require much water to carry out and can be done without much equipment either, making it useful for farms with limited resources.

Once beans are picked and sorted, this method involves simply drying the entire freshly picked coffee cherry outside with the seed still inside.

The drying stations used for this can vary considerably. Some may consist of simple brick patios or roofs, while others will use tables or specially constructed drying beds that enable better air flow to the cherries to achieve more even drying.

To avoid mould, fermentation and rotting, the cherries must be turned regularly, typically by hand and with simple rakes. Once the cherries are sufficiently dry, the dried fruit flesh can then be removed, leaving the green coffee ready to be stored before transportation.

Considerations

-

Natural processing comes with more risk of defect than other methods, which can be devastating for farms and communities. If the drying cherries are not raked and monitored carefully, the fruit may start to spoil and ferment in a way that ruins the final flavour of the coffee and makes it unsellable.

-

When processed well, natural coffees can unleash unique coffee notes that some believe contribute to the finest coffees. This is a result of the bean absorbing essences of the fruit’s drying flesh.

-

This method is only really possible in places where temperatures are hot enough to dry coffee in a way that does not lead to mildew, meaning areas with high mist levels are not suitable.

-

There is an obvious excitement among some producers, roasters and coffee buyers for the way this method can produce coffee with incredibly unique profiles. A well processed natural coffee can bring out incredible cupping notes and offer amazingly sweet flavours.

Natural processing comes with more risk of defect than other methods, which can be devastating for farms and communities.

The Washed Process / The Wet Process

Most specialty coffee tends to be washed. And the appeal for many is that washed coffee can be incredibly clean and bright, which is particularly suited to producers in places like Colombia and Africa where coffee offers higher levels of acidity that can be accentuated with the right methods.

Once beans are picked, the washed process requires the removal of each layer of the coffee cherry before it’s dried. This means that, unlike with natural or honey processed coffees, producers don’t utilise the fruit flesh to provide additional flavour.

Removing the fruit flesh is done with a machine called depulper. After depulping, the beans are put in a water tank where a fermentation process will remove the remainder of the fruit flesh. Beans are then rinsed and dried in a similar way to naturals, often on large patios and drying beds but sometimes with a mechanical drying machine.

Considerations

-

This method is more reliable, both in terms of the flavours it will produce as well as the reduced chance of batches being ruined by defects.

-

It generally produces coffee with higher acidity (or brightness) and will be favoured by producers and roasters who want to showcase this characteristic.

-

Washed coffees are reliant on the inner bean having gained enough carbohydrates and flavour during its growth. The coffee should be tasty enough to stand on its own, without the need for additional flavours from the fruit during the drying process. Some believe this means that the washed process highlights the true character of a coffee bean.

The washed process generally produces coffee with higher acidity (or brightness) and will be favoured by producers and roasters who want to showcase this characteristic.

The Honey Process / The Pulped Natural Process

The honey process sits somewhere between natural and washed. These coffees are known for providing a good level of fruitiness as well as medium sweetness.

In this process, the skin of the cherry is removed but a specific amount of mucilage (fruit pulp) is intentionally left on the beans before they are sent for drying.

That mucilage, which is what the ‘honey’ actually refers to, rather than the sweet taste of honey, stays on the seed as it dries in the sun afterwards. The seed must be raked and rotated carefully to avoid mould until the seed finishes drying.

Considerations

-

As there is less flesh surrounding the beans, the effects that would come from the natural process are lessened (e.g absorption of flavours from the fruit) but the sweetness in the cup can still be increased considerably by the sugars in the flesh that remains.

-

A perfect result might be a coffee that offers the brightness of washed coffee and the low acidity and fruitiness of natural coffees.

-

Producers can play with the amount of fruit pulp left on the bean to influence the overall profile of the final coffee once it’s brewed. Typically, the more mucilage (fruit flesh) left on the bean, the sweeter it will taste.

Producers can play with the amount of fruit pulp left on the bean to influence the overall profile of the final coffee once it’s brewed. Typically, the more mucilage (fruit flesh) left on the bean, the sweeter it will taste.

The Semi-Washed Process / Giling Basah

The semi-washed process is most popular in Indonesia where it’s referred to as Giling Basah. After being picked, coffee beans are depulped and then briefly dried until the moisture content is somewhere around 30%, rather than the normal 11-12% with washed coffees.

Next, the coffee is hulled, stripping off the outer parchment and exposing the green beans beneath, which are then dried again until they are dry enough to be stored. The result of all this is a bean that is much darker in colour as well as lower acidity and more body.

Considerations

-

Certain flavours are also likely to emerge, which some consider to be a defect while others see merely as a trait of coffee produced in places like Sumatra, Indonesia. These can include tobacco, leather, spices and wood.

-

There is disagreement in the coffee industry about whether or not the semi-washed process actually leads to desirable characteristics with some feeling that the resultant flavours dominate the actual flavour of the original single origin bean.

Read Our Beginner’s Guide On How to Buy Specialty Coffee Beans

Experimental Coffee Processing Methods

There is now more coffee experimentation going on than ever before. Farmers are encouraged by higher market prices for unique and experimental coffees and are therefore investing in new technologies and farming processes to meet this demand. Some recent additions to the world of coffee processing are below.

|

The Anaerobic Process

|

Anaerobic fermentation is similar to the washed process but instead allows fermentation to take place in fully sealed oxygen-free tanks. This has been known to lead to unexpected and exciting flavours.

|

|

The Carbonic Maceration

|

Carbonic maceration is where coffee cherries are placed into carbon-dioxide rich barrels to ferment. This processing typically creates bright coffees with notes of red fruits.

|

What Happens Next?

After coffee is processed, the bean will be encased by a layer of protective parchment (unless using the semi-washed process) until it is ready to be shipped (typically 30–60 days after it has “rested”). Finally, this layer of parchment is then removed to reduce the weight and bulk of the shipment, making it less expensive.

The hulling is done mechanically in a dry mill (different to a wet mill/depulper). These dry mills often use machines to sort the coffee based on colour, defects and size. Inadequate beans will be rejected or sorted into a lower quality batch.

In specialty coffee, it’s also common for beans to be sorted and graded by hand to further refine the batch and ensure it’s fit for the higher prices it’s sold for. This is time-consuming and adds a significant cost to the whole process, but also has a huge impact on how much farmers will make for their yields due to the quality levels that are achieved.

Once the beans have been sorted and graded, they are packed into 60kg or 69kg jute bags, depending on the country of origin and exported abroad.

Final Thoughts

More producers today are adapting their processing methods to achieve specific qualities and flavours, partly as a way of increasing the attractiveness of their beans to roasters and importers in the specialty coffee market.

However, the biggest concern for the majority of coffee farmers around the world is still avoiding defects in their batches and safeguarding their eventual returns. The choice about whether to use washed, natural or honey processing is often driven by which is the most likely to guarantee a good yield.

For the consumer, processing methods remain just one indicator of what you’re likely to taste in the cup. And although you might develop a preference for coffee processed using a certain process, each variation we’ve explored can lead to exceptional tasting coffee. In our eyes, no single method is necessarily better than another.

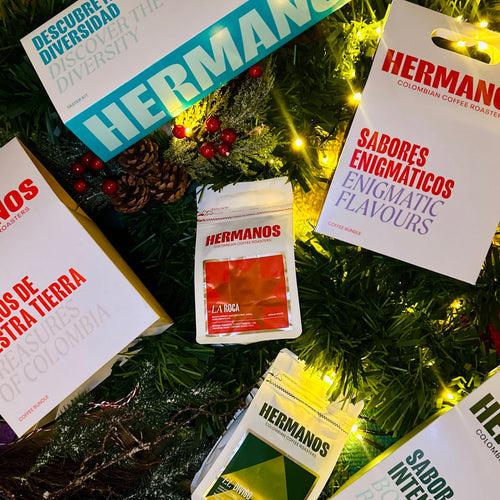

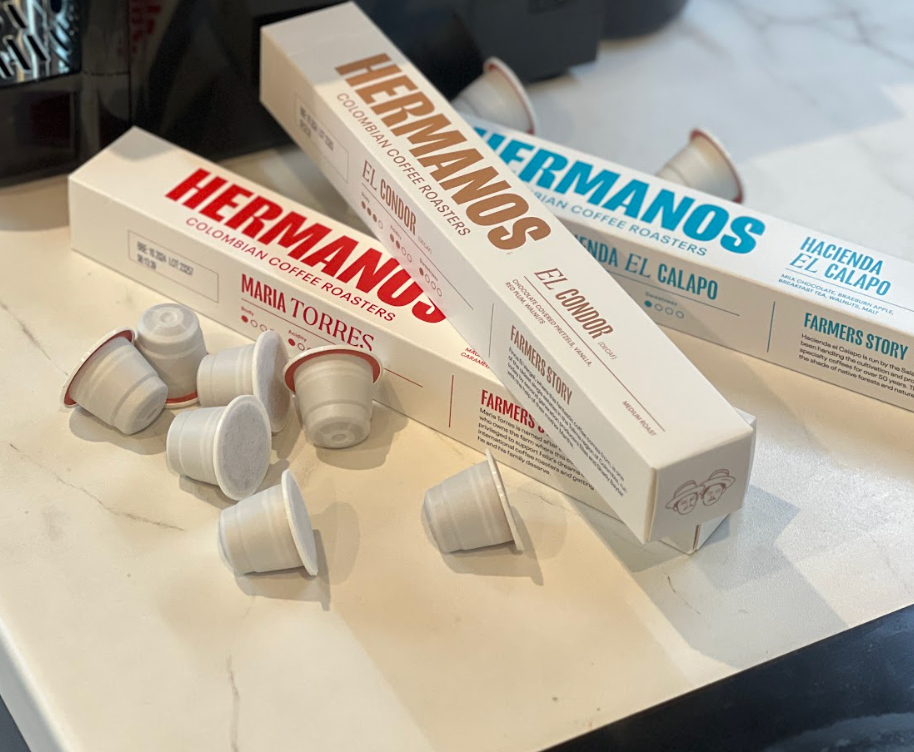

If you’d like to compare coffee processed with different methods, our range of Colombian coffee beans will always include information about the processing method used by an individual farmer or cooperative.

Explore Our Full Range of Single Origin Colombian Coffee Beans